How Is Sheet Metal Made

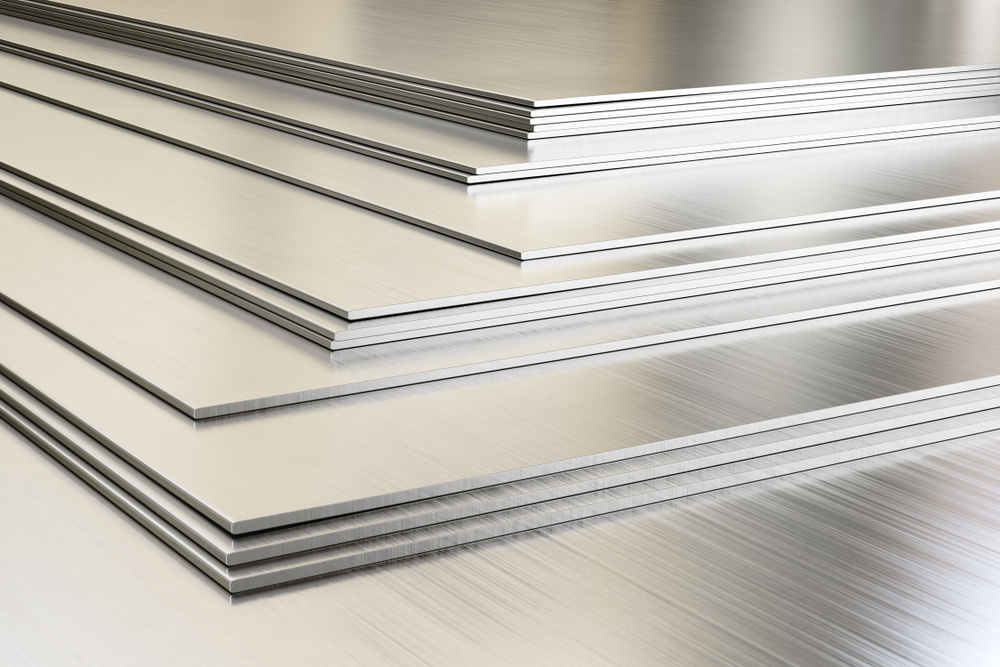

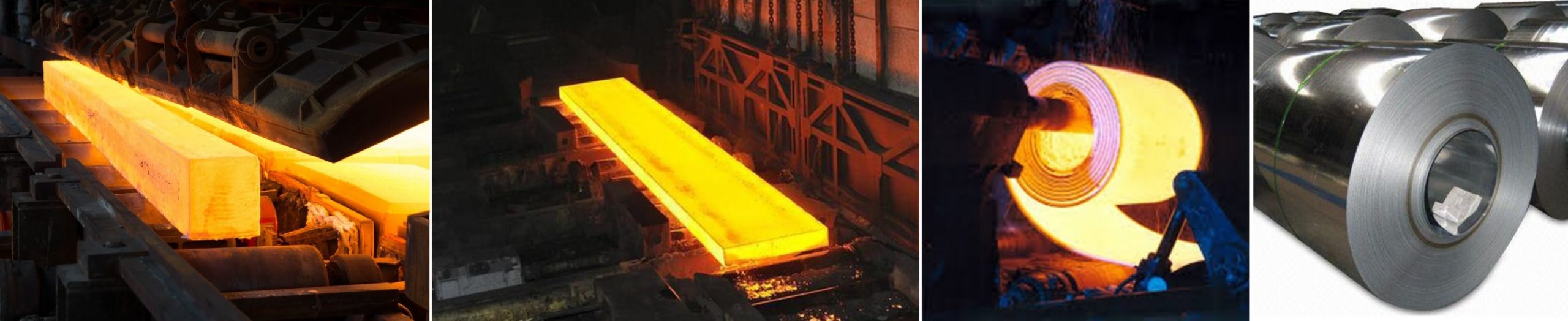

How Is Sheet Metal Made - Sheet metal is made for a wide range of purposes, from automotive parts. Web the 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Web there are four basic stages in the process of making sheet metal: Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25. Melting, pouring, pickling and lastly, rolling and annealing. Web sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending,. Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Sheet metal is made for a wide range of purposes, from automotive parts. Melting, pouring, pickling and lastly, rolling and annealing. The process typically uses coating, cutting, bending,. Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25. Web the 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Web there are four basic stages in the process of making sheet metal: Web sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Web the 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. The process typically uses coating, cutting, bending,. Web there are four basic stages in the process of making sheet metal: Melting, pouring, pickling and lastly, rolling and annealing. Sheet metal is made for a wide range of purposes, from automotive parts. Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25. Web sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Hillman 24in x 30in Steel Solid Sheet Metal in the Sheet Metal

Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25. Melting, pouring, pickling and lastly, rolling and annealing. Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Web sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into.

What Exactly is Sheet Metal Fabrication and Why Do We Offer It?

Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25. The process typically uses coating, cutting, bending,. Web the 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and.

How Sheet Metal Is Made KNS Metals

Melting, pouring, pickling and lastly, rolling and annealing. Web sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. Web the 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal.

How Is Sheet Metal Made? (And A Bit About Finishes) ACRA Machinery

The process typically uses coating, cutting, bending,. Melting, pouring, pickling and lastly, rolling and annealing. Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Web there are four basic stages in the process of making sheet metal: Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25.

SUS 316l Stainless Steel Sheet , 0.7mm Thickness Alloy Steel Sheet

The process typically uses coating, cutting, bending,. Web the 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25. Web there are four basic stages in.

How Sheet Metal Is Made & Its Uses Service Steel Warehouse

Web sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. Web there are four basic stages in the process of making sheet metal: Sheet metal is made for a wide range of purposes, from automotive parts. Extremely thin sheets are considered foil or leaf ,.

How Is Sheet Metal Made? Sciencing

Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25. Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Melting, pouring, pickling and lastly, rolling and annealing. Web sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into.

How is sheet metal made? Westberg Sheetmetal

Web the 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is made for a wide range of purposes, from automotive parts. Web there.

A Guide To How Sheet Metal Is Produced Radshape Limited

Web there are four basic stages in the process of making sheet metal: Melting, pouring, pickling and lastly, rolling and annealing. Sheet metal is made for a wide range of purposes, from automotive parts. Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process. The process typically uses coating, cutting, bending,.

What Are The Different Types Of Sheet Metals For Fabrication?

Web the 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. Web there are four basic stages in the process of making sheet metal: Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25. Sheet.

Web The 4 Primary Steps Are The Melting Of Your Chosen Material, Pouring It Into A Rectangular Mold, Pickling (Removing Impurities), And Rolling And Annealing The Metal Into A Sheet.

Web sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25. Web sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. Melting, pouring, pickling and lastly, rolling and annealing.

Web There Are Four Basic Stages In The Process Of Making Sheet Metal:

Sheet metal is made for a wide range of purposes, from automotive parts. The process typically uses coating, cutting, bending,.